In today's fast-paced global marketplace, efficiency is paramount for businesses aiming to excel in procurement. One critical tool that can significantly enhance operational efficiency is the use of pallet jacks. According to a report by MarketsandMarkets, the global material handling equipment market is projected to reach $200 billion by 2026, with pallet jacks playing a pivotal role in achieving streamlined logistics and inventory management. By optimizing the handling of bulk materials and reducing physical strain on workers, pallet jacks not only improve productivity but also contribute to a safer workplace environment.

Moreover, a study published by the Occupational Safety and Health Administration (OSHA) indicates that material handling incidents account for nearly 25% of all workplace injuries. Implementing pallet jacks can drastically lower these risks by providing a more ergonomic solution for moving heavy items. By integrating this essential equipment into their operations, procurement professionals can not only bolster their efficiency but also promote a culture of workplace safety. This guide will delve into the various types and applications of pallet jacks, equipping businesses with the knowledge needed to drive their global procurement success.

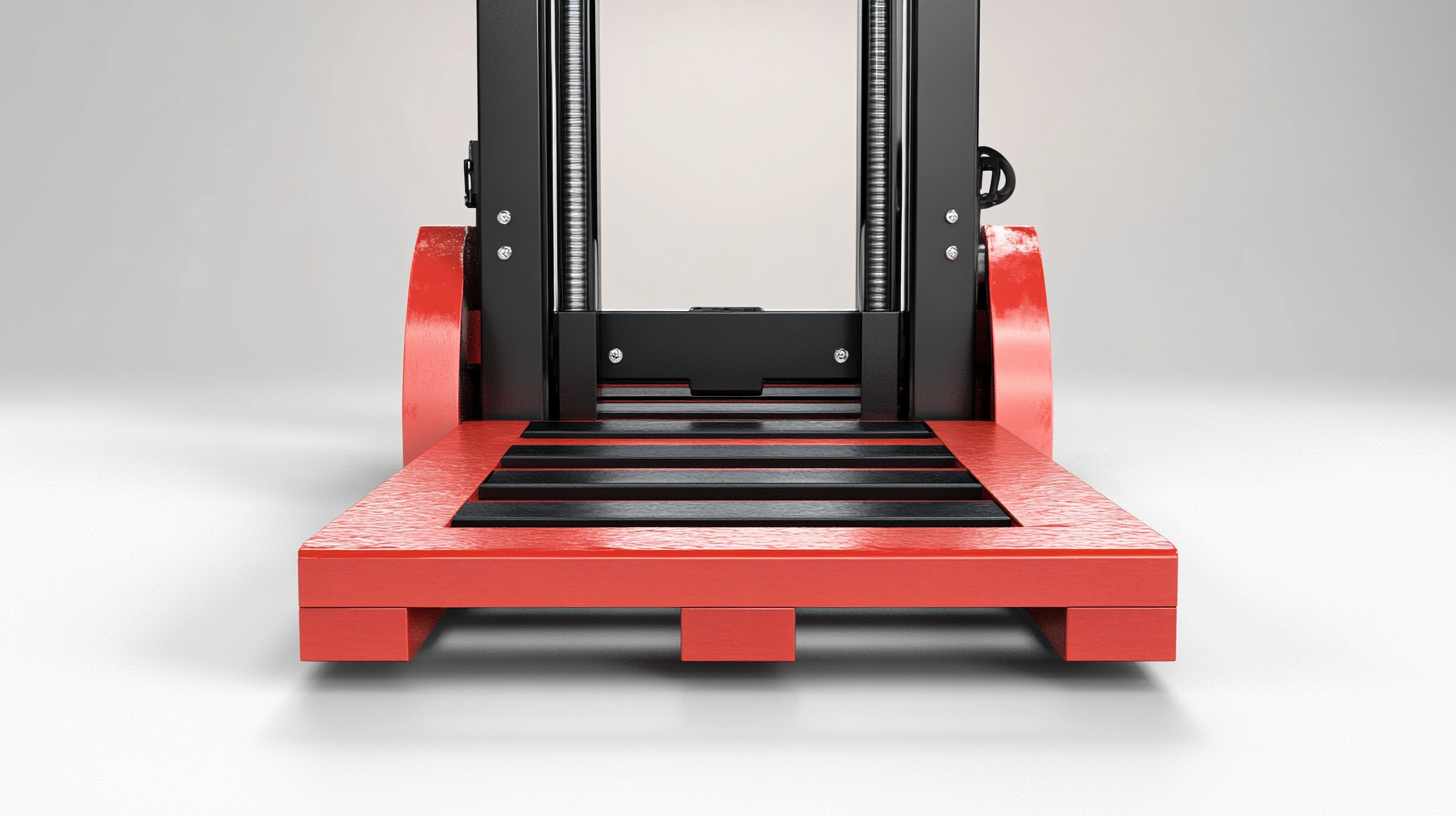

Pallet jacks, also known as pallet trucks, are essential tools in the logistics and procurement sectors. Their primary function is to lift and transport pallets filled with goods, making them crucial for efficient warehouse operations. With various designs available, from manual push pallet jacks to electric models, they cater to different needs, contributing to the overall effectiveness of managing inventory and supplies. Understanding the role pallet jacks play in procurement is vital for businesses aiming to streamline their processes. They facilitate quick movement of goods within warehouses, reducing the time required for manual handling. This not only accelerates the handling of incoming and outgoing shipments but also minimizes potential damage to products, ensuring that quality is maintained throughout the supply chain. Moreover, the use of pallet jacks can significantly enhance labor efficiency. By allowing workers to move heavier loads with less effort, companies can optimize their workforce and allocate resources to other essential tasks. This increased productivity ultimately supports global procurement efforts, ensuring that businesses stay competitive in an ever-evolving marketplace while maintaining a focus on operational efficiency.

When it comes to optimizing logistics and procurement processes, selecting the right pallet jack is crucial. An efficient pallet jack not only enhances productivity but also contributes to the overall success of global procurement strategies. Understanding the key features to look for can make a significant difference in operational efficiency.

First and foremost, the load capacity of a pallet jack is vital. It's essential to choose a model that can safely handle the weight of your goods. Most standard pallet jacks can lift up to 5,500 pounds, but if your operations require heavier loads, look for heavy-duty options. Additionally, the lifting mechanism should be considered; hydraulic jacks often provide smoother operation and are easier to maintain than electric models, especially when used in less intensive environments.

Another critical feature is maneuverability. A pallet jack that is ergonomically designed can significantly reduce operator fatigue, especially during long shifts. Look for models with adjustable handles and easy-to-turn wheels, as these can enhance control and reduce the risk of accidents in crowded spaces. Furthermore, examining the wheel material is important; rubber wheels offer better grip and shock absorption on uneven surfaces, whereas polyolefin wheels are ideal for smooth floors, providing fast and agile movement.

Finally, consider the overall durability and maintenance requirements of the pallet jack. Choosing a model constructed from high-quality materials ensures longevity and reduces the need for frequent repairs, ultimately saving costs in the long run. In addition, jacks with fewer moving parts tend to be easier to maintain, allowing for quick fixes and less downtime. By focusing on these key features, businesses can select pallet jacks that significantly boost operational efficiency and enhance their procurement success.

Efficient warehouse operations are crucial for global procurement success, and pallet jacks play a significant role in this efficiency. To optimize the use of pallet jacks, warehouses must first focus on staff training. Employees should be well-versed in the various types of pallet jacks and their specific use cases. Proper training not only ensures safety but also increases productivity, as workers can seamlessly maneuver and operate pallet jacks to move inventory quickly.

Additionally, implementing a systematic organization of goods can enhance the efficiency of pallet jack use. By arranging items in designated zones or logical groupings, workers can minimize travel time and streamline the picking process. This organized approach allows for faster handling and reduces the likelihood of inventory errors. Furthermore, maintaining pallet jacks in good condition through regular inspections and preventative maintenance is essential. Well-maintained equipment reduces downtime and ensures that staff can rely on their tools for daily operations, thereby contributing to an overall increase in warehouse efficiency.

Finally, considering the layout of the warehouse is critical in maximizing the effectiveness of pallet jacks. A well-designed space with wide aisles and clear signage can facilitate smoother operations, allowing workers to navigate swiftly and safely. By optimizing these elements, warehouses can leverage pallet jacks not just as tools for lifting and moving goods, but as integral components in a comprehensive strategy for operational excellence in global procurement.

Training your team for effective pallet jack utilization is crucial for enhancing operational efficiency in any warehouse or distribution center. Pallet jacks are versatile tools that can streamline the movement of goods, but their effectiveness largely depends on the proficiency of the personnel using them. A comprehensive training program ensures that your staff is not only familiar with the equipment but also understands its safety protocols and best practices for usage.

An effective training regimen should cover various aspects, including the mechanics of the pallet jack, optimal load handling techniques, and the importance of maintaining proper posture during operation. By incorporating hands-on practice sessions, employees can gain confidence and competence in maneuvering pallet jacks in tight spaces, loading and unloading goods, and efficiently navigating through aisles. This practical experience not only enhances safety but also minimizes the risk of damage to goods and equipment.

Moreover, fostering a culture of continuous improvement is essential. Regular refresher courses and skill assessments can keep your team sharp and informed about any new technologies or techniques that emerge in pallet jack operations. Encouraging team discussions about challenges faced during shifts and sharing solutions can also promote knowledge sharing and camaraderie among staff members. Ultimately, a well-trained team can significantly impact your global procurement success by ensuring a smooth, efficient workflow that meets operational demands.

Maintaining pallet jacks is crucial for ensuring their long-term efficiency and reliability in any procurement operation. Regular maintenance not only prolongs the life of the equipment but also minimizes the risk of unexpected downtimes that can disrupt supply chain processes. One key aspect of maintenance is conducting routine inspections. Regularly checking for wear and tear, particularly on wheels and forks, helps identify issues before they escalate. Operators should also be trained to recognize signs of mechanical defects, ensuring that malfunctions are addressed promptly.

Another important maintenance practice is proper lubrication. Parts like wheel bearings and pivot points require adequate lubrication to function smoothly. Neglecting this can lead to increased friction, resulting in wear and potential failure. Establishing a maintenance schedule that includes lubrication types and frequency aligned with the workload can optimize performance. Additionally, cleanliness plays a vital role in maintenance; keeping pallet jacks free of debris and contaminants minimizes the risk of damage and facilitates smoother operations.

Proper battery care is essential for electric pallet jacks. Regularly charging the battery and following the manufacturer's guidelines for maintenance will ensure reliability during work hours. If you notice a decline in performance, it may be time to assess battery health and replace it if necessary. By prioritizing these maintenance practices, businesses can ensure that their pallet jacks remain efficient and reliable tools in the pursuit of global procurement success.

Content © 2025 Komatsu. All Rights Reserved