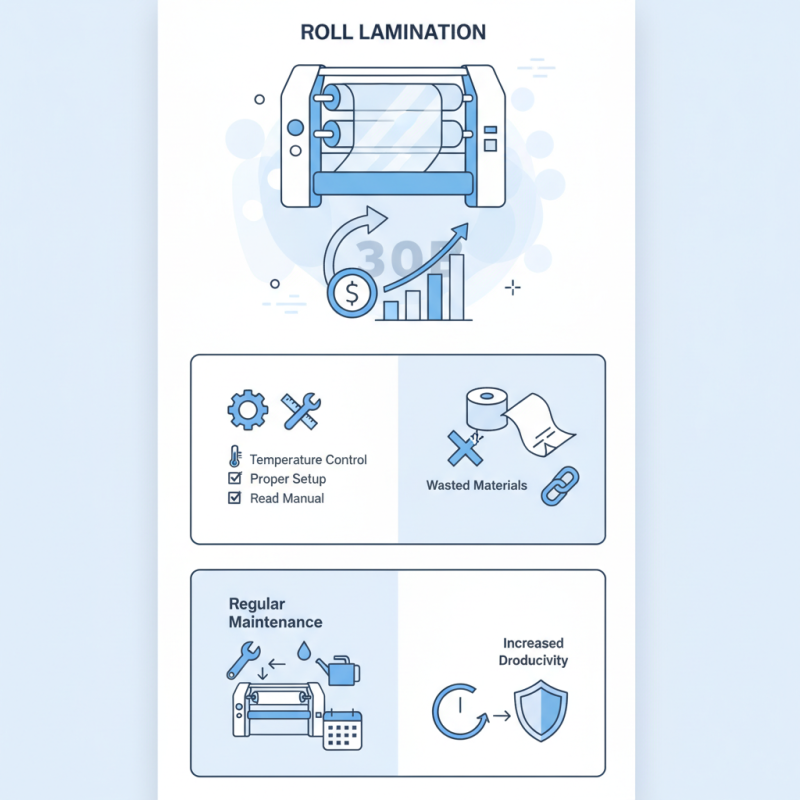

The use of a Roll Lamination Machine has become increasingly essential in various industries. Reports indicate that the lamination market is projected to reach $30 billion by 2025, reflecting the rising demand for quality finishing solutions. As businesses strive for durability and presentation, a roll lamination machine stands out for its efficiency and versatility.

However, operating such machinery is not without its challenges. Many users overlook the significance of proper setup, which can lead to wasted materials and subpar outputs. For instance, inconsistent temperature settings can compromise the adhesion quality. It's crucial to stay informed about the machine's specifications and best practices to avoid common pitfalls.

Moreover, the importance of regular maintenance cannot be understated. Neglecting routine checks can result in costly downtimes and decreased productivity. A well-maintained Roll Lamination Machine ensures consistent performance and longevity. By understanding these critical tips, users can enhance their lamination processes and achieve superior results.

Roll lamination machines are essential tools in many industries. They provide a durable, protective layer to documents, artwork, and more. Understanding their basics helps users operate these machines effectively.

When using a roll lamination machine, ensure you adjust the temperature correctly. Too high can lead to bubbles. Too low can fail to seal properly. This can waste materials and time. Test on a scrap piece first.

Keep the rollers clean. Dust and debris can affect the lamination quality. A simple cloth can do wonders. Regular maintenance is crucial to extend the machine's life.

Another helpful tip: monitor the film’s thickness. Too thick may jam the machine. Too thin might tear easily. Experiment to find the best fit for your needs. Roll lamination can be tricky. Learning comes with practice and patience.

When working with a roll lamination machine, safety cannot be overlooked. A significant number of injuries occur due to negligence. According to industry reports, improper handling leads to over 30% of workplace accidents in lamination settings. It’s crucial for operators to familiarize themselves with the machine’s safety features.

Before starting, inspect your workspace. Remove any obstructions that could cause trips. Ensure that safety shields are in place. Follow all operating procedures. Wearing protective gloves and eyewear is a must. The heat and pressure involved can be hazardous. Being aware of your movements can prevent accidents.

Additionally, keep hands clear of rollers and avoid loose clothing. These small details can have big impacts. Training can’t be minimized. Most accidents happen in environments lacking effective training programs or safety protocols. Implement regular safety drills to maintain awareness.

Good communication with your team is vital. If someone sees a potential risk, they should speak up. Machines require respect. Never rush the laminating process. Errors can lead to waste and even injuries. Safety should always take precedence in your workflow.

| Tip/Safety Precaution | Description |

|---|---|

| Read the Manual | Familiarize yourself with the machine's features and operational guidelines. |

| Wear Safety Gear | Always use appropriate safety equipment, including gloves and goggles. |

| Check Electrical Connections | Ensure all plugs and outlets are secure before operating. |

| Adjust Temperature Settings | Set the correct temperature for the laminate material being used. |

| Monitor the Laminating Process | Keep an eye on the machine during operation to spot any issues. |

| Keep Work Area Clean | Maintain a tidy workspace to avoid accidents and equipment damage. |

| Use Correct Lamination Film | Choose the appropriate film based on your project requirements. |

| Turn Off When Not in Use | Ensure the machine is powered down when not in operation for safety. |

Preparing materials for lamination is a crucial step for achieving optimal results. Begin by selecting the right type of paper or material. Ensure that it's clean and free of dust or debris. Edge alignment is essential; misaligned edges can lead to uneven laminations. Trim materials to the desired size. If you’re unsure, a test run with scrap paper can help.

Tips: Use a ruler and sharp cutting tool for accurate edges. This step can prevent future issues. Sometimes, we rush this process, resulting in errors. Take your time here; it’s worth it.

When you load materials into the roll lamination machine, ensure they are flat. Wrinkles or folds can ruin your project. Monitor temperature settings; too high or too low affects adhesion. Familiarize yourself with the machine’s settings before starting a large project.

Tips: Keep your workspace organized. It can save you a lot of time later. Mistakes happen, and frustration builds. It's important to maintain patience throughout the process and refine your approach as needed.

When operating a roll lamination machine, proper maintenance is crucial for efficiency and longevity. Regularly inspecting and cleaning the machine can prevent common issues. According to industry reports, up to 30% of downtime in laminating processes results from equipment malfunction. Addressing these problems promptly can save significant time and resources. Cleaning rollers and checking alignment should be routine tasks.

It's important to keep the machine lubricated. Proper lubrication reduces friction and wear. A report from the Laminating Industry Association indicates that machines lacking adequate lubrication can suffer a 25% decrease in productivity. Operators should also be aware of the quality of the films used. Using subpar materials can lead to waste and operational issues. Poorly laminated products may have delamination or bubbling defects.

Finally, operators need to undergo proper training on the machine's functions. Mistakes in loading or settings can result in flawed outputs. Experience suggests that worker training can improve output quality by 40%. Reflecting on these practices can lead to enhanced performance and safety in operations. Each step in maintenance impacts overall efficiency and effectiveness.

When using a roll lamination machine, issues may arise that can disrupt the workflow. Identifying these problems quickly is vital for maintaining production efficiency. It's noted that nearly 25% of issues stem from incorrect temperature settings. If your laminated product shows bubbles or wrinkles, it might be due to inadequate pressure or inconsistent heat. Adjusting these parameters may solve the problem.

Another common issue is misalignment of the material. A study reveals that about 15% of lamination failures occur from misaligned laminates. This often results in uneven edges or exposed areas. Regularly checking the alignment guides can help prevent this. Operators should also be aware that dirt or dust on the rollers can impact quality, leading to a slower production rate.

In some cases, the lamination film itself can cause problems. Reports show that using the wrong gauge of film leads to a 20% increase in errors. It's essential to ensure the selected film matches the intended use. When unforeseen issues arise, take a moment to reflect on past mistakes. This can lead to better practices in the future. It's a journey of continuous improvement.

Content © 2025 Komatsu. All Rights Reserved